Specification Plating

Specification Plating

Epner works in accordance with all applicable ASTM, AMS, MIL, and Prime Contractor specifications. Epner maintains a Quality System implementing ISO 9001:2008.

Read More

Difficult Substrates

Difficult Substrates

These metals often require special processing procedures to ensure a successful finish, and may also be rare or very expensive to manufacture, machine and subsequently finish.

Read More

Base Metal Substrates

Listed in this section are the common base metal substrates Epner Technology plates on.

Read More

Plating on Plastics

Plating on Plastics

Epner specializes in plating a variety of di-electric materials including the engineering plastics such as Ultem™, Teflon™, Ryton™ and Torlon™…and of course ABS.

Read More

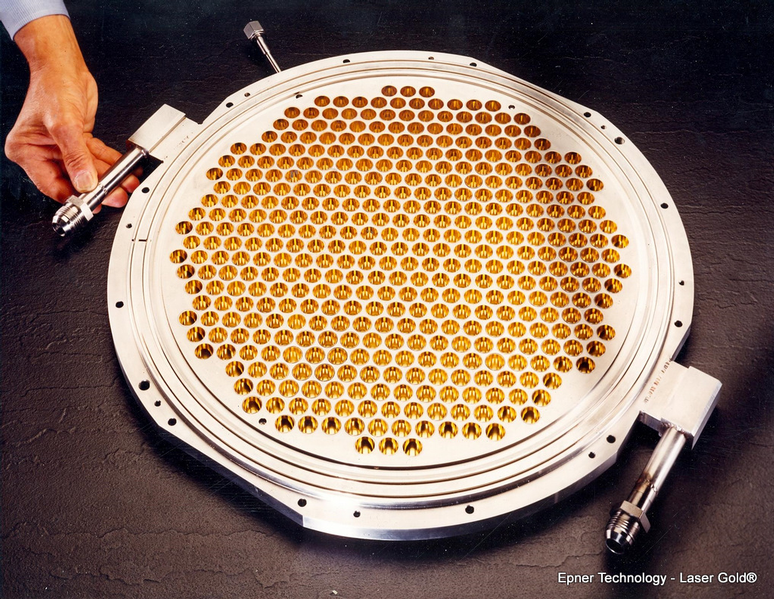

Turn-Key Manufacturing

Turn-Key Manufacturing

As a key plating supplier to some of the finest CNC machinists, wire EDM shops and optical fabricators, including single point diamond machining, what can be more natural than to team with these “known quality” customers and add them to our Approved Vendor List.

Read More

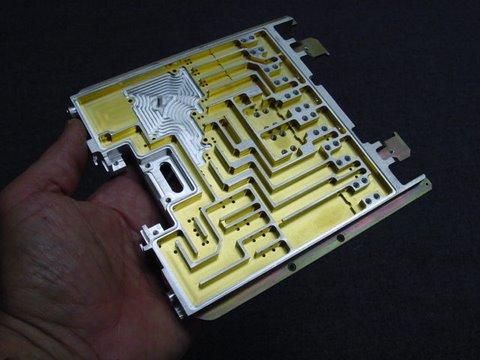

Masking

Masking

Selective plating is one of Epner’s specialties. Skilled artists, in many cases, hand paint with a proprietary masking material in areas to be kept free of plating. In some cases, your part would be plated all over and the masking would be applied to the surfaces we wish to maintain plating, while the rest of the part is stripped. Pull plugs, threaded Teflon and occasionally custom machined shields are all part of Epner’s masking arsenal.

Read More

Brush Plating

Brush Plating

A form of tank-less plating, ETI’s brush plating capability offers a unique and highly advanced solution to many plating issues and limitations. Please consult with an Epner sales representative for any plating inquiries.

Read More

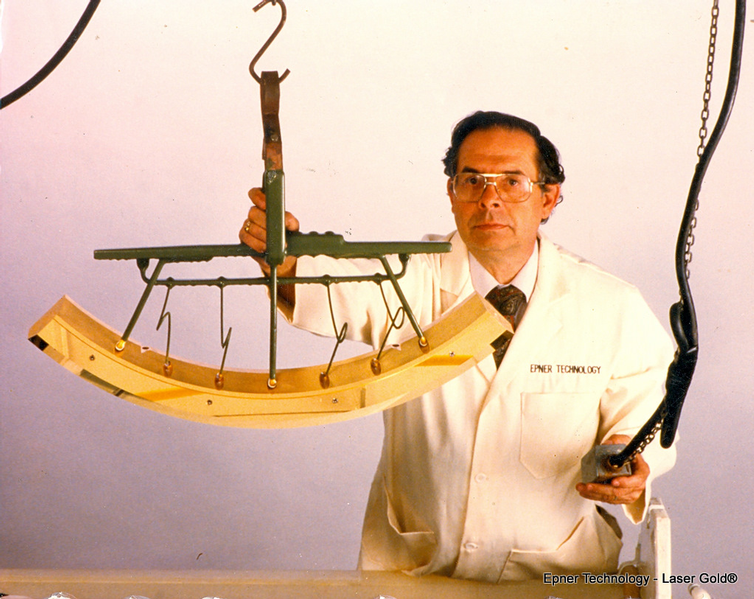

Refining

For the last 40 years, Epner Technology has done its own gold refining utilizing the remarkable gold and silver recovery system. A product of Precious Metals Processing Consultants, Inc.

Read More

Polishing & Buffing

Because of Epner’s critical role in the coating of optics, our polishing capability is frequently confused for optical polishing or lapping. Polishing done at Epner Technology is probably better characterized as buffing. This process has achieved surface roughness averaging less than 5 nano meters Ra (the equivalent of 5 nano meters = 50 angstroms).

Read More

Research and Development

Research and Development

Epner Technology is nearly 100 years old! In those years, vast amount of plating know-how has been accumulated, and that knowledge has been brought to bear on numerous engineering problems in our research and development laboratory.

Read More

Repair, Replate & Salvage

Epner is frequently called upon to salvage components from the diverse worlds of art, motorcycles, automobiles and church ware, because it requires great skill and technical know-how to strip off the old plating in order to replate to specification.

Read More