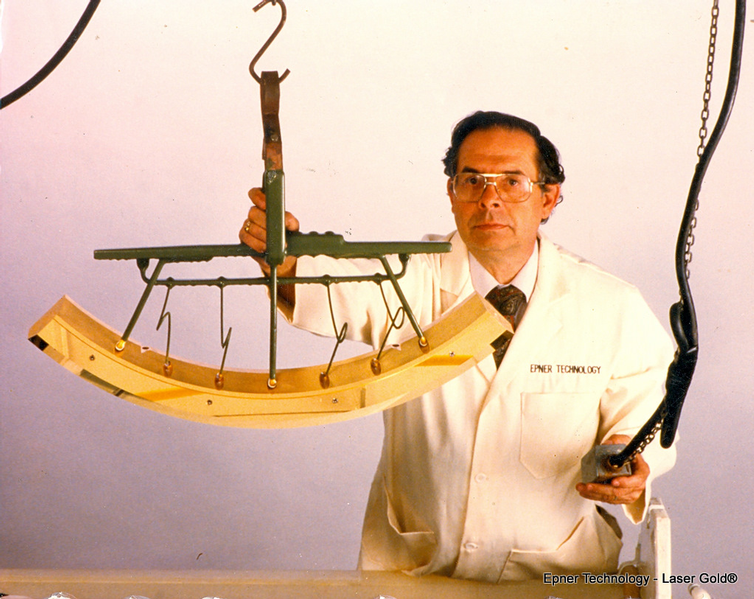

Defense and Military

Defense and Military

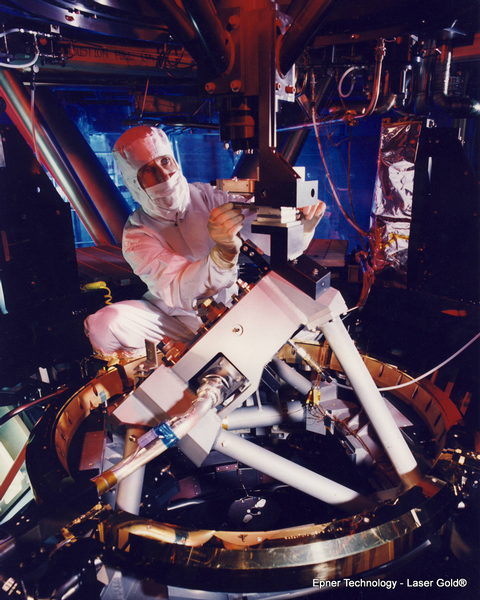

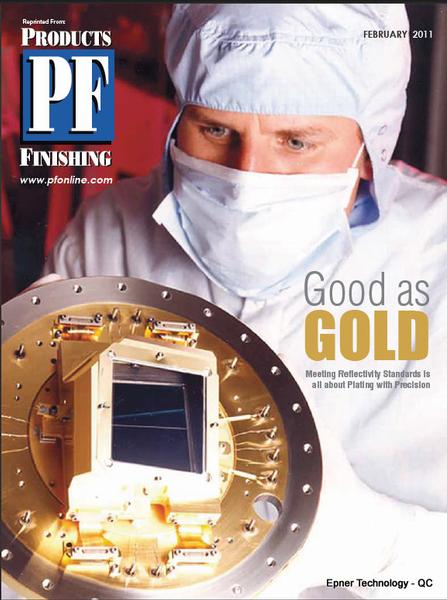

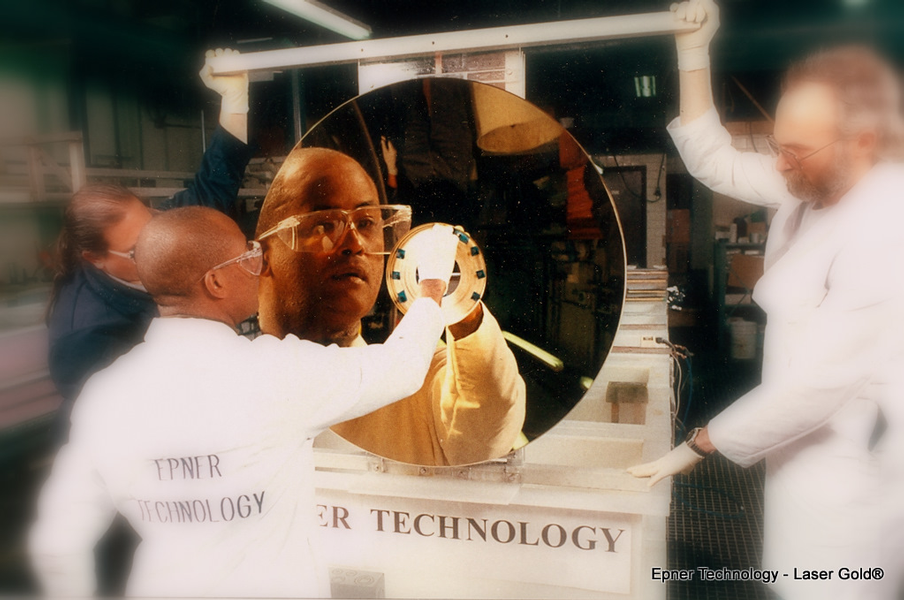

This section has only a few examples of the hundreds of space and terrestrial projects involving Epner Technology’s vast experience in these markets. Many of these projects overlap in the area of space, optics and astronomy.

Read More

Space, Satellites and Astronomy

A broad range of products built for space and astronomy applications performed “as designed” thanks to Laser Gold’s incredible low emissivity and/or high reflectivity. See a partial list of high-tech projects in which Epner Technology proudly has been involved with:

Read More

Contract Machinists and Fabricators

Contract Machinists and Fabricators

The contract or machining job shops are among Epner’s most important customer base. These shops invest time and money in creating some of the most complicated and exotic machined parts.

Read More

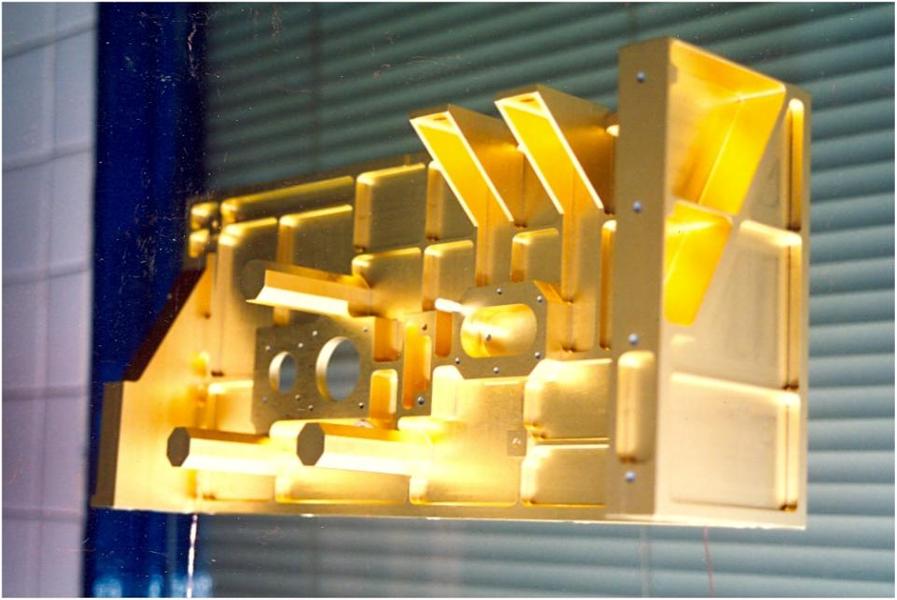

Microwave and Electronics

Microwave and Electronics

Epner technology was in the beginning of microwave itself. That was in 1938 when we were tasked with silver and gold plating the earliest “plumbing” as the wave guides and co-ax lines were then called, for systems that were being sent to England as an early warning system for the incoming German bombers during the Battle of Britain.

Read More

Laser, Optics and Photonics

Laser, Optics and Photonics

With the advent of diode pumped technology, Epner’s main Yag business is refurbishment (including the electroformed Quantronix cavity) of existing cavities while moving on to tubular chambers pumped by diode lasers through a side wall slot. Laser Gold was named because of its near universal acceptance as the most efficient and durable YAG Laser Pump Cavity coating. ETI provides solderable gold plating for diode pumped heat sinks.

Read More

Gas Sensors

Gas Sensors

Numerous gas sensing systems using Infrared Light rely on Epner’s Laser Gold to achieve the ultimate in sensitivity and long life. Epner presently supplies this service to manufactures of gas sensors and analyzers in seven countries worldwide, and many of the manufactures of these products combine Epner’s electroforming capability with this unique gold coating.

Read More

Semi-Conductor

Semi-Conductor

Epi Reactors, Rapid Thermal Heaters and Memory Disk Heaters all have been improved by re-plating with Laser Gold. ETI both fabricates from scratch or re-plates your existing reflectors on the AMT, ASM, Intevac and Moore Technology heater systems. A patented improvement in the reflector increased shape for EPI reactors has produced the ability to guarantee lamp life for one year with uniformity at the wafer.

Read More

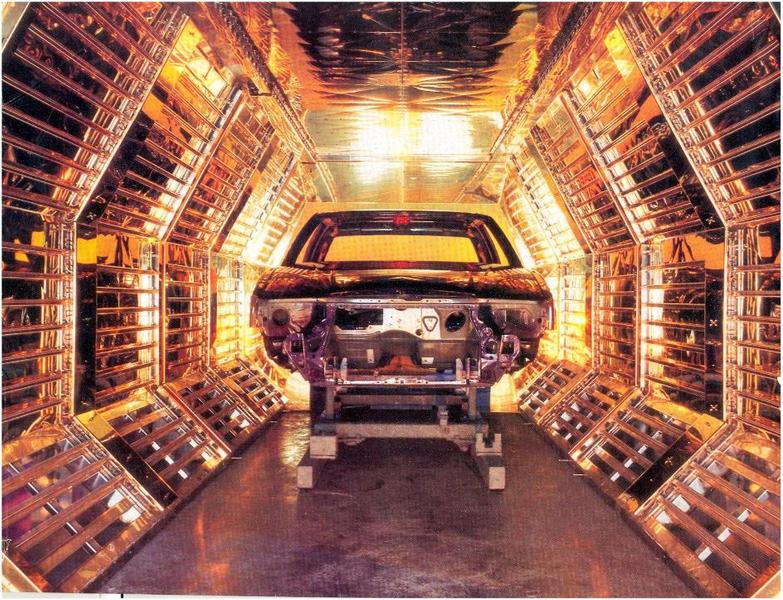

Automotive

Automotive

ETI has produced Laser Gold plated reflector panels for some 37 auto paint drying tunnel ovens. An experiment at Ford’s Wixom pilot line produced an incredible 36% increase in oven efficiency when compared to the original stainless steel oven walls.

Read More

3D Printing

We have been assisting 3D printing houses with rapid-prototyping as well as decorative plating jobs. Epner Technology specializes in plating non-conductive substrates including but not limited to PLA, SLA & UV Resins, Thermoplastics, LOM & DLP polymers, Glass and non-glass Nylons. We can offer assistance to those seeking production quantities or one-off special projects.

Read More

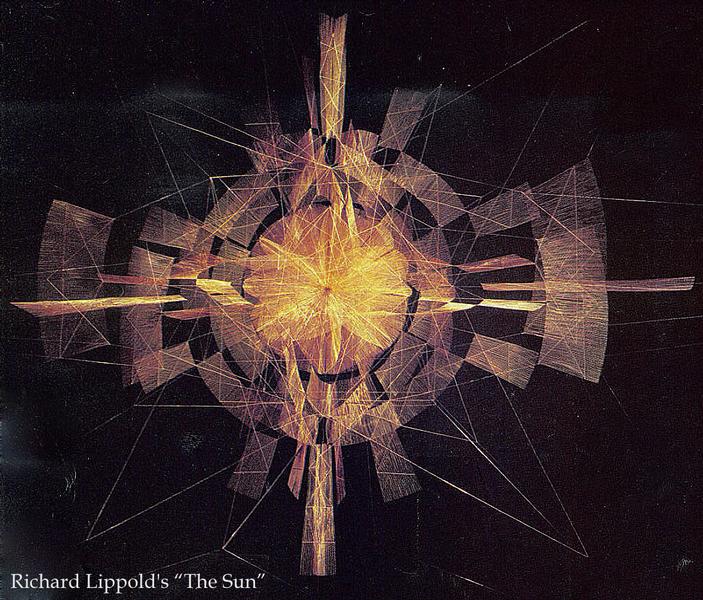

Artists and Sculpture

Realizing a need in the art community for a plating company that welcomes their chance to contribute to their creativity rather than find them an annoyance, Epner Technology set up a division that draws on its high technology know-how and applies it to the world of art, sculpture and jewelry.

Realizing a need in the art community for a plating company that welcomes their chance to contribute to their creativity rather than find them an annoyance, Epner Technology set up a division that draws on its high technology know-how and applies it to the world of art, sculpture and jewelry.

Read More

Medical

Medical

A variety of medically related products from radio opaque markers on catheters to lightpipes used in tympanic (ear) thermometers are made possible with Laser Gold.

Read More

Research and Development

Research and Development

Epner Technology is nearly 100 years old! In those years, a vast amount of plating know-how has been accumulated, and that knowledge has been brought to bear on numerous engineering problems in our research and development laboratory.

Read More

Other Platers

Other Platers

Two factors have combined to make ETI the “platers plater.” First and most important is our reputation among our peers for consistent quality and on-time delivery.

Read More