Read Blog Entitled: One Of The Most Momentous event in Epner’s 100 Year History

Laser Gold is our proprietary hard gold plating process that has been refined for more than twenty years and has been named the sole and single NIST standard (#1929) for infrared reflective efficiency.

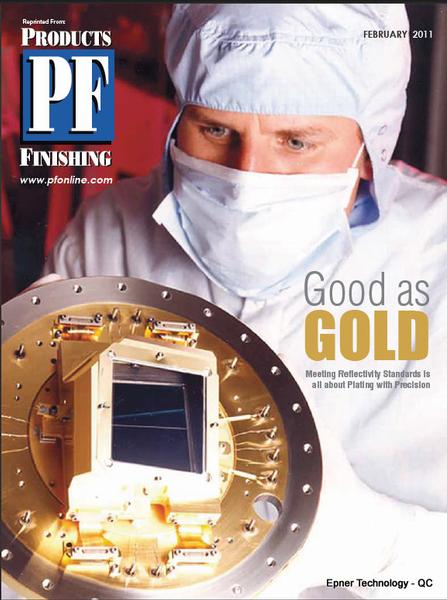

Laser Gold plating is a proprietary, pure, hard, electrochemically deposited gold coating that combines the theoretical reflectivity and emissivity of gold, with a surface that can actually be physically cleaned! Laser Gold has been specified on many of our nation’s most advanced military and space programs.

Epner Technology took part in a specialized study of infrared reflectivity organized by the NIST’s Physics Laboratory, Optical Technology Division, which performed an intercomparison calibration study of near-normal diffuse and specular reflectance measurements amongst twenty DoD and Contractor Laboratories. Epner Technology supplied NIST with the twenty Laser Gold plated standard mirrors used in this prestigious study. The goal of this study was to lead to improved measurement accuracy, produce readily available standards based on results of Intercomparison, and expand NIST’s capabilties with IR reflectance measurements. After completion of this collaborative study with NIST, Epner Technology is proud to announce the availability of a Laser Gold coated IR standard traceable to NIST. Price upon request. Click on the button below to to gain access to download the full report.

-

“Gold coat per Epner Technology, Brooklyn, New York Laser Gold specification #2011”.

With this call out your parts will be plated with a .25 micron of Laser Gold. This assumes the component will be received at Epner ready for Laser Gold plating that is in nickel or copper or stainless steel. No polishing at Epner is anticipated.

Read More The Laser Gold Story

The Laser Gold Story

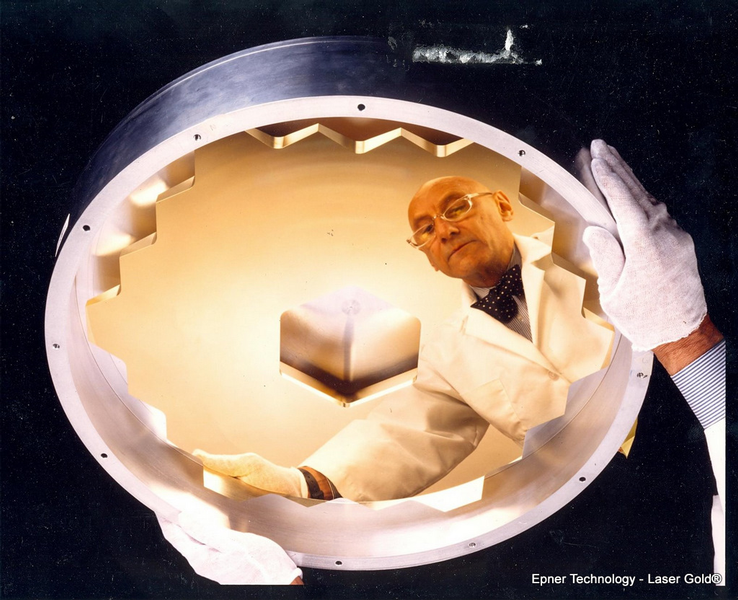

The hard gold plating process that changed the direction of Epner Technology’s future; the fusing reflector for the Xerox Model 3100 copier.

Read More

-

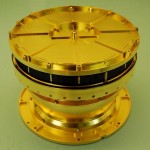

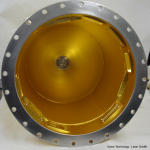

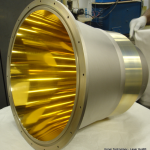

Plated Aluminum/AlBeMet Housing

Laser Gold Examples

COHERENCE MODEL FOR LASER & SOLAR SCATTERING BY DIFFUSE METALS

COHERENCE MODEL FOR LASER & SOLAR SCATTERING BY DIFFUSE METALS

Conventional physical models of light scattering often neglect the fundamental wave nature of light, inevitably leading to inaccuracy. From its early applications to radiation sources, coherence theory is currently being extended to the description of light scattering, providing more accurate predictions and discoveries of effects beyond the assumptions of conventional models. Advanced Optical Technologies (AOT) has developed several coherence models of light scattering that have been verified against radiometric and materials data, including AFM data for rough surfaces. Applications including bio-medical imaging and diagnosis, computer-graphic design, and radiometric M&S and data analysis benefit from physical models of light scattering that account for wave effects. Epner Technology supplied AOT with diffuse gold samples for this exciting study. For more information on this study see the scatterometry page at Advanced Optical Technologies.

By Advanced Optical Technologies – Brian Hoover, Dave Taliaferro, Dave Bowers (ATA), Dave Wellems (ATA) and Victor Gamiz (AFRL)