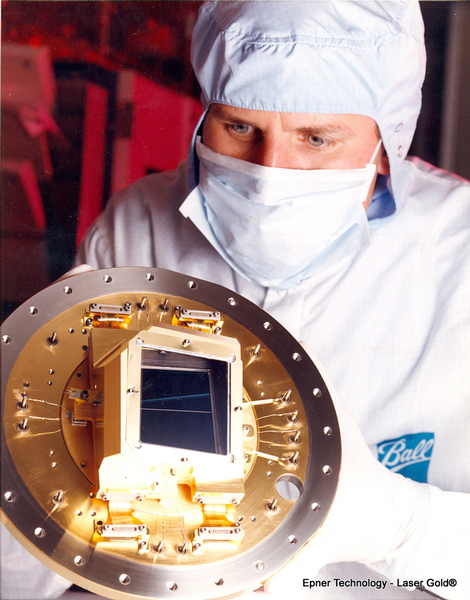

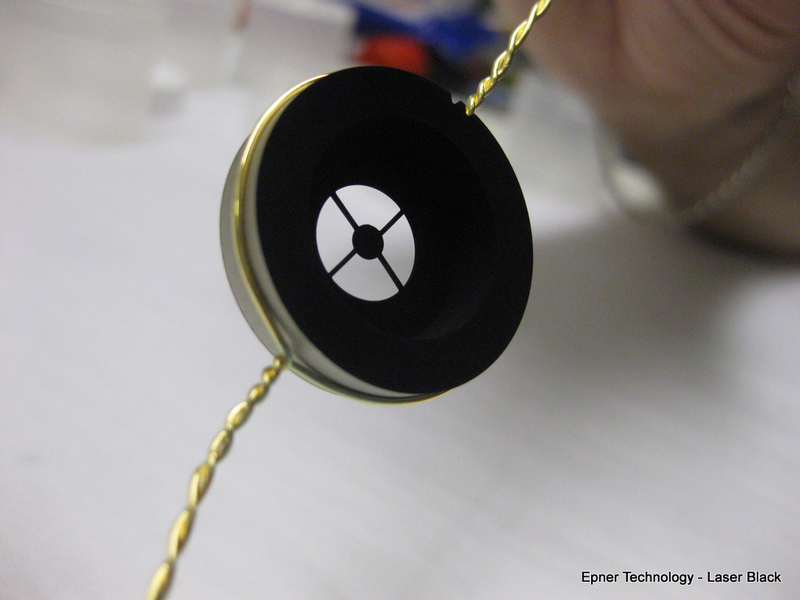

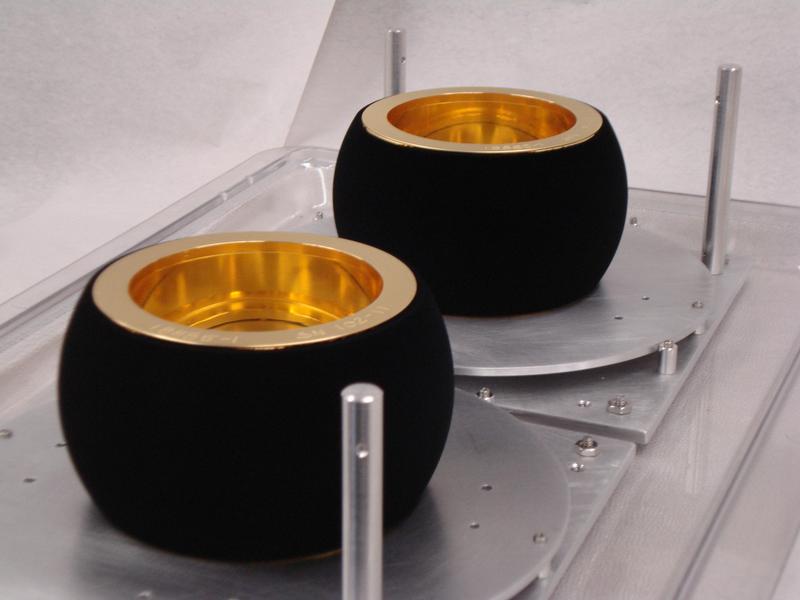

Laser Black is a multi-layer metallic oxide. Its deep velvety-black surface is somewhat fragile since it achieves its remarkable absorption by creating a micro-dendritic structure on the optical surface (see Laser Black SEM Photo). Unfortunately, these dendrites will show evidence of being touched, however the overall performance of the surface will not be degraded if this “touching” is performed in a small area. Being an inorganic coating, Laser Black does not outgas, and when vibrated ultrasonically in acetone, shows no flaking or chipping.

Laser Black is a multi-layer metallic oxide. Its deep velvety-black surface is somewhat fragile since it achieves its remarkable absorption by creating a micro-dendritic structure on the optical surface (see Laser Black SEM Photo). Unfortunately, these dendrites will show evidence of being touched, however the overall performance of the surface will not be degraded if this “touching” is performed in a small area. Being an inorganic coating, Laser Black does not outgas, and when vibrated ultrasonically in acetone, shows no flaking or chipping.

Irradiation of Laser Black

Irradiation of Laser Black- Maryland University Training Reactor (MUTR) is currently in the process of testing the irradiation of Epner Technology’s Laser Black coating on an aluminum substrate. The samples of our Laser Black UV-absorbing coating has finished the preliminary tests using low levels of irradiation (click “Read More” for the testing results). Larger doses will be used in the coming weeks. The data will be added to this page once it’s available. The University will also be undertaking measurements at NIST on the specular and diffuse reflectivity of Laser Black in the vacuum ultraviolet region of the electromagnetic spectrum. This measurement will require use of the NIST SURF III Synchrotron. The results of this measurement will also be made available.

Read More - Specifying Laser Black

-

“Laser Black per Epner Technology spec 3688”

Your product will be plated with a duplex copper coating, and then a velvet-like copper oxide is formed. A fifty year old process was significantly modified in ETI’s Lab in order to achieve a coating that one expert said, “swallows light.” Under certain conditions a roughening of the substrate may take place prior to copper plating.

Read More